Asher Guitars & Lap Steels was founded by master luthier Bill Asher, whose career began humbly at the workbench, repairing and restoring guitars for Los Angeles’ thriving music scene. Those early years taught him the nuances of tone, feel, and playability—and how the smallest detail could transform an instrument into a musician’s lifelong partner. Bill’s meticulous craftsmanship and deep understanding of players’ needs drew the attention of some of the world’s most respected artists such as Jackson Browne, Neil Young, Paul Simon and Ben Harper.

Over the years, Asher Guitars has built instruments for a long list of notable players across genres—touring professionals, studio legends, and passionate collectors who all share a desire for unmatched tone and playability. Each build reflects a perfect balance of artistry and engineering, resulting in guitars that look, feel, and sound extraordinary.

In 2021, Asher Guitars began a historic collaboration with Doug Irwin, the visionary behind many of the Grateful Dead’s most iconic guitars. As an Irwin Certified Builder, Bill Asher is entrusted to carry forward Irwin’s celebrated legacy of craftsmanship and innovation. Together, they are creating instruments, such as the Dire Wolf Bass, that honor Irwin’s historic designs while infusing them with Asher’s own refined techniques—bridging generations of guitar-making mastery.

While Asher’s reputation for exceptional lap steels helped define the brand, that celebrated line now continues under the dedicated Electro Hawaiian company. This move allows Asher Guitars to focus entirely on expanding its electric and custom build offerings, while the Electro Hawaiian name carries forward the lap steel tradition with the same commitment to quality.

Today, Asher Guitars stands as a boutique builder with a global reputation—serving artists and enthusiasts who demand instruments with soul, character, and enduring beauty. Every guitar is custom crafted in Los Angeles, crafted to be played for a lifetime and treasured for generations.

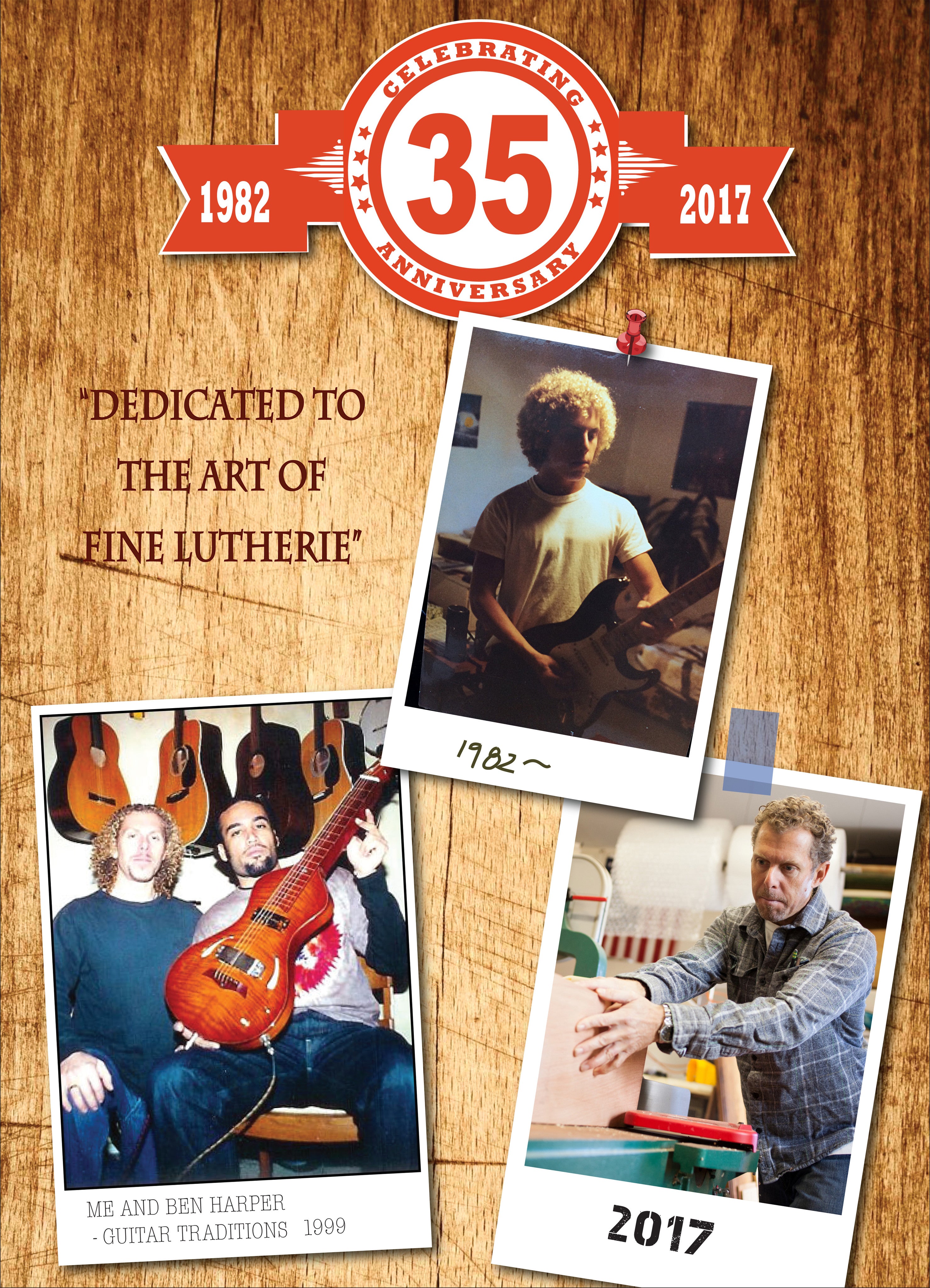

Bill Asher is a master luthier whose journey began in his high school wood shop class in 1982, where he discovered his passion for shaping wood and creating instruments. After graduation, he apprenticed under renowned luthier Jeff Lunsford, eventually purchasing the shop and gaining extensive knowledge in guitar repair and restoration. Over the years, Bill honed his craft further by working with acclaimed builders Rick Turner and Mark Lacey, absorbing invaluable techniques and insights that would inform his own designs. While he continues to perform occasional repairs for his loyal clients, Bill has focused on developing his own innovative guitar creations. Today, he is embarking on an exciting new chapter as a certified Irwin builder, collaborating with legendary luthier Doug Irwin. Their partnership, highlighted by the creation of the Dire Wolf Bass played by Oteil Burbridge of Dead and Co, is making guitar history, blending craftsmanship, innovation, and legacy in groundbreaking ways.

Bill Asher is a master luthier whose journey began in his high school wood shop class in 1982, where he discovered his passion for shaping wood and creating instruments. After graduation, he apprenticed under renowned luthier Jeff Lunsford, eventually purchasing the shop and gaining extensive knowledge in guitar repair and restoration. Over the years, Bill honed his craft further by working with acclaimed builders Rick Turner and Mark Lacey, absorbing invaluable techniques and insights that would inform his own designs. While he continues to perform occasional repairs for his loyal clients, Bill has focused on developing his own innovative guitar creations. Today, he is embarking on an exciting new chapter as a certified Irwin builder, collaborating with legendary luthier Doug Irwin. Their partnership, highlighted by the creation of the Dire Wolf Bass played by Oteil Burbridge of Dead and Co, is making guitar history, blending craftsmanship, innovation, and legacy in groundbreaking ways.

Jessica Asher is the co-owner and operations manager of Asher Guitars and Electro Hawaiian, where she combines creative vision with technical expertise to guide both brands. With a background in CNC, CAD, and CAM programming, Jessica specializes in precision milling, ensuring every instrument meets exacting standards of craftsmanship and performance. Her work bridges the artistry of lutherie with advanced manufacturing processes, allowing for both innovation and consistency in production.. She has a masters degree from Boston University.

Jessica Asher is the co-owner and operations manager of Asher Guitars and Electro Hawaiian, where she combines creative vision with technical expertise to guide both brands. With a background in CNC, CAD, and CAM programming, Jessica specializes in precision milling, ensuring every instrument meets exacting standards of craftsmanship and performance. Her work bridges the artistry of lutherie with advanced manufacturing processes, allowing for both innovation and consistency in production.. She has a masters degree from Boston University.

Not all guitars are created equal.

Asher Guitars still employs old world lutherie techniques using hand tools, elbow grease, and persistence combined with the precision of modern technology from power tools and CNC machines. The technical blend of old meets new results in a masterfully designed, beautifully sounding instrument of professional quality that will last generations.

So how does our process work?

Quality starts at the beginning: The wood. Bill Asher hand selects the finest tone woods for grain structure, weight and color. All of our wood is sustainably and or responsibly sourced. Our wood also meets CITIES guidelines and any old growth wood that we obtain is accompanied with the proper regulatory paperwork. The Asher shop is run entirely on solar power, and we make our best efforts at producing zero waste of wood products. We respect trees as a valuable environmental resource so we recycle, reuse or donate all sawdust, shavings and wood pieces.

Rough cutting: Planks of wood are rough milled to various dimensions, depending on model, specific part or type of guitar. The wood is then allowed to cure before it is hand cut to the final shape with guidance from our precision templates. Figured top woods, binding and purfling are added. Guitar tops of flamed or figured woods of certain thicknesses are book matched together, then glued to the body. Binding or purfling is then added to routed channels then glued and clamped into place.

Precision: CNC machines are used to help make the necks and some of the Asher guitar bodies. Accuracy in guitar necks and bodies is beneficial because it allows for increased consistency throughout and a clean-entry, snug fit into the neck pocket. The CNC technique also routes perfect channels for our custom compression truss rods that are easily adjustable under full string tension. After the necks are CNC carved, we manually do a final hand shaping to get the desired profile. Fret slots, which are precisely cut by CNC, are carefully hand fretted. We spend extra time with our attention to detail to achieve an optimal feel.

Finishes: Nitro, Poly, Gloss, Stain or Relic? We offer both nitrocellulose and polyester lacquer finishes, as well as relic’ing of varying degrees on either finishes. These finishes are performed by a handful of skilled artists that can create the perfect sunburst or custom color. A nitro cellulose finish usually takes at least 8 weeks for multiple rounds of spraying, sanding, curing and buffing. Polyester finishes are shot with a high quality material that is sprayed as thin as possible. This is a fantastic finish option that offers a great sound quality and increased durability. Satin nitro finishes and oil stains are also available.

Relic’d finishes and aged hardware add an authentic road-worn look to any guitar. Subtle or extra rugged, Bill Asher performs all the relicing by hand with techniques learned from some of the top relic specialists in the business.

Electronics, machineries and details: For some, electronics are everything. For us, they are important, but just part of the equation to achieving a great sounding guitar. Pickups, knobs, tuners, bridges, switches etc. are specifically chosen components, many of which are custom made for our guitars.

Final Assembly: Putting the guitar together is usually the most fun and gratifying part (next to seeing it played live at the Greek Theater in front of ten thousand people.) We finally get to see all the parts come together creating a unique, handcrafted instrument. This is our opportunity to make any final adjustments and tweaks and to check the sound quality and playability to make sure it meets our rigorous standards and passes the test.

These guitars are certified Bad Ass.